Save over 40% of electrical energy and subsequent tonnes of CO2 using our ‘Green Mode’ solutions.

Learn moreWelcome to Weiss Technik UK

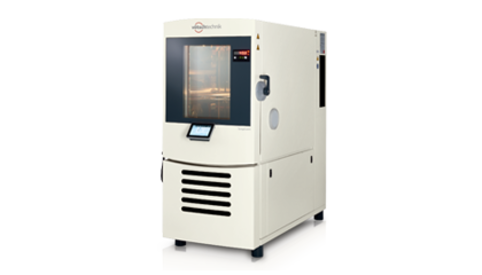

We are the world market leader for environmental simulation systems and leading in heat technology, climate technology and pharmaceutical systems.

Close